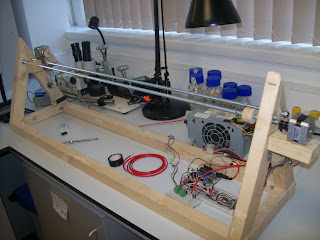

Mk2 H&E machine

A long long time ago in a lab... not very far away I built a rail for automating H&E because it's boring and I don't like doing it.

Time passed an I changed job and all the bits became parts of other things.

Now it looks likely I'll be doing some H&E again I'm going to build a new one, hopefully better than the last one.

Things to improve:

Time passed an I changed job and all the bits became parts of other things.

Now it looks likely I'll be doing some H&E again I'm going to build a new one, hopefully better than the last one.

Things to improve:

- Speed - The threaded bar was very accurate but very slow.

- Homing - Each run required the user to position the head and all parts of the protocol were distances from the start. I want this to be able to home itself.

- Aesthetics - The last one worked but did not inspire confidence. Also there was a lot of places liquid could get in and electricity could get out.

Current idea:

- Belt drive should be faster.

- End stops will allow homing at the start and protect against over-run problems = 2x micro switch.

- Aluminium and plastic? I can almost mill plastic on my CNC accurately?!? = Spending some actual money rather than building from scraps and left overs.

Quick sketch on openSCAD...

Comments

Post a Comment